Condensing Boilers

Condensing Boilers

Condensing boilers utilise the heat recovered from condensing the water vapour in the flue gases, which would normally be discharged into the atmosphere, to improve the overall efficiency, providing:

Reduced fuel usage.

Lower TCO and justified return on investment.

The latent heat of combustion of the water vapour present in flue gases (natural gas or LPG only) is only available when the return water temperatures are below 55°C however, so attention to the overall system design is required to utilize the efficiency increases available. At best, the efficiency of condensing boilers is up to about 109% net (98% gross) with 30°C return water temperatures. With more traditional water temperatures of 80°/60°, the efficiency falls to around 96%, and a standard premium efficiency hot water boiler will have similar efficiency levels at a significantly reduced cost.

The water vapour is a product of the combustion of the hydrogen element in the fuel and when combined with other gases, the condensation products are corrosive. Accordingly, special attention must be given to using corrosion resistant materials in the condensing section of the boiler to collect and dispose of the condensate, as this is acidic, and Cooke Industries only offer AISI316L and AISI316Ti stainless steel solutions in our condensing boiler range for the widest acceptance of water conditions and the greatest lifespan.

Typically the flue gas temperatures are 10-20K above the return water temperature, and attention to the flue design and material choice is also required for condensing boilers. We can offer 316L stainless steel and polypropylene flue systems for these applications. Additionally, the condensate may require neutralizing before disposal into drainage systems to meet Local Body requirements, and we have a range of condensate neutralizer kits for our boilers.

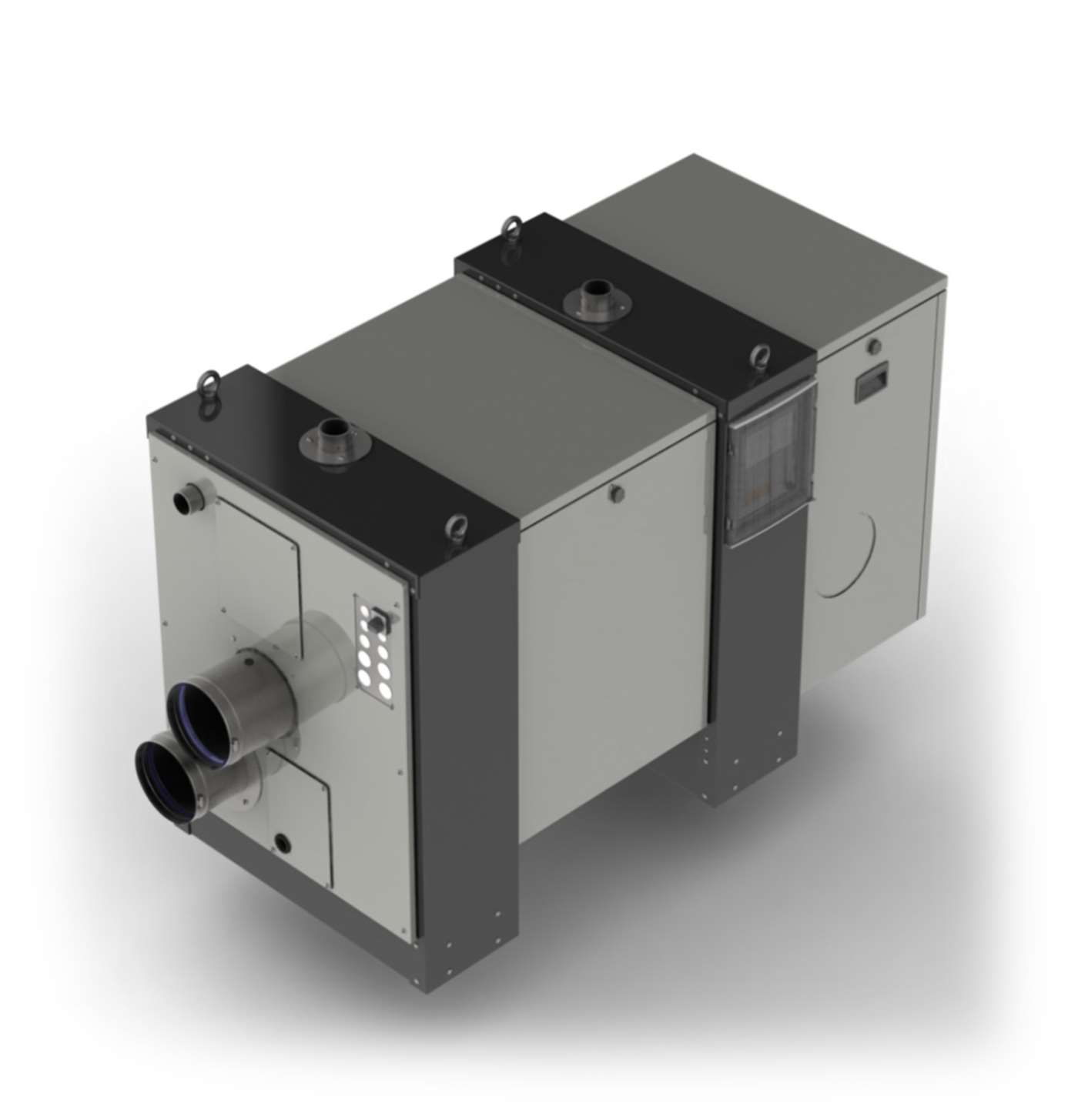

Cooke Industries offer a full range of modular wall hung, floor standing, and heavy duty LPHW condensing boilers designs for a wide variety of applications from commercial to industrial, with individual sizing from 85kW up to 3MW, with cascade options for larger duties.

Products

Products

Related Products

Enquiry about Condensing Boilers

Got any questions?