Ductwork

New Zealand’s most automated duct shop delivers precision bespoke ductwork for seamless HVAC integration.

With 100 years of proven fabrication expertise, Cooke Industries combines cutting-edge automation with SMACNA 2021-compliant construction (DW144 optional) to produce leak-tight systems that perform across all pressure classes.

Advanced Automation & Technology

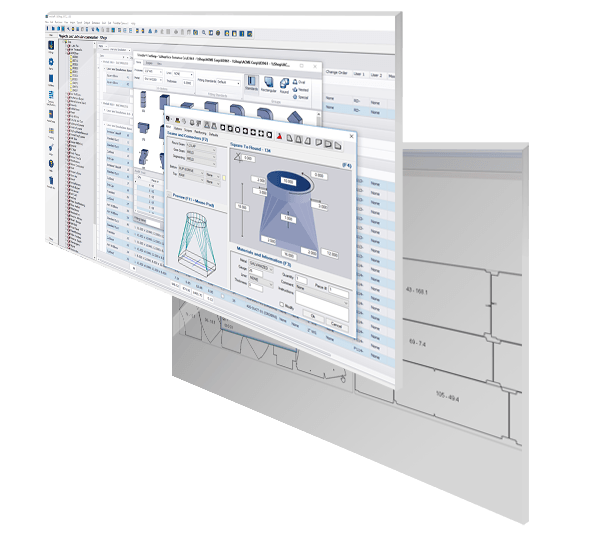

Trimble AutoBid – Instant automated take-offs and accurate costing

Trimble FabShop CAD – Optimised nesting and detailed 3D modelling

Lockformer/Mestek fully automated coil line – NZ’s only system for zero-waste rectangular duct and fitting blanks

Spiro International fully automated spiral tube-former setting the benchmark for exceptional build quality and durability in high-speed spiral duct production

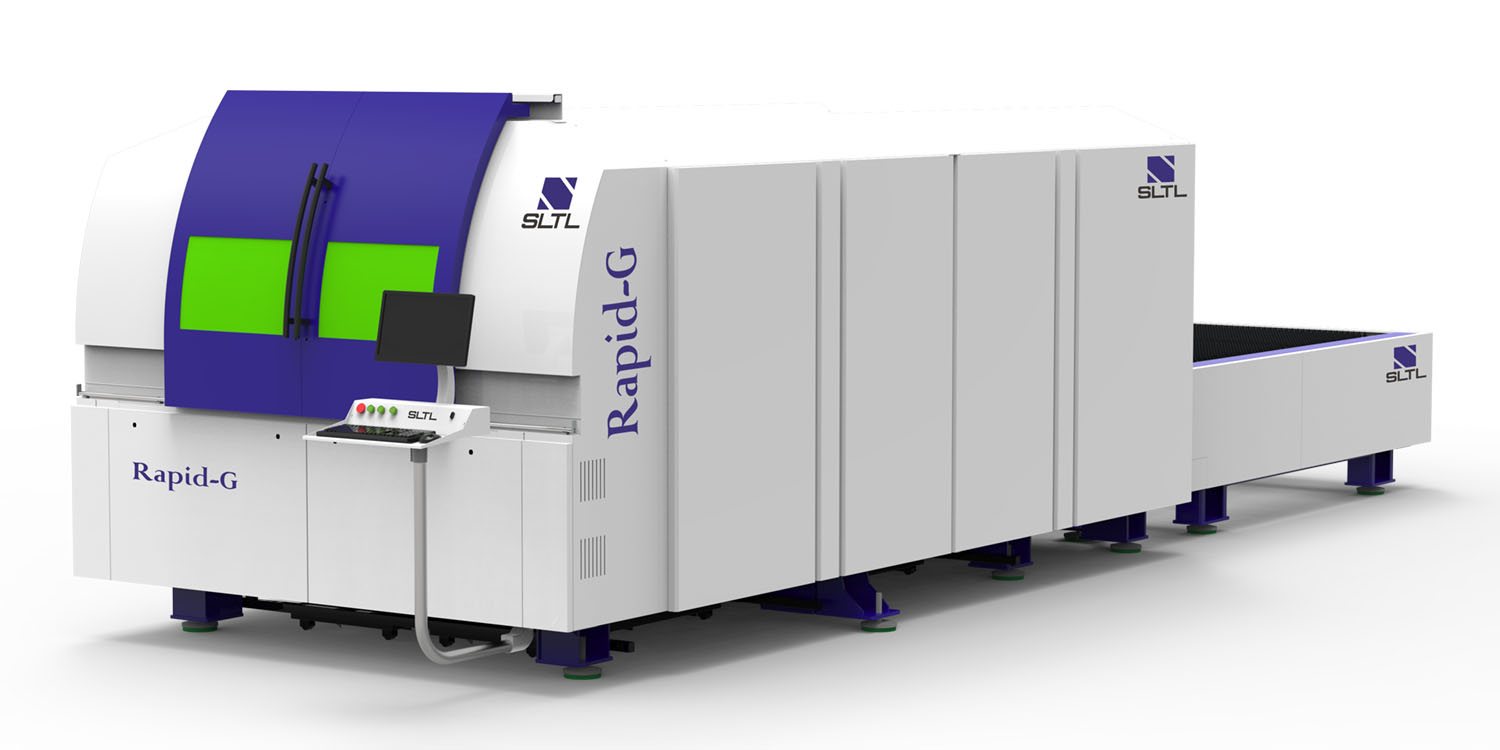

Dual-table fibre laser cutter - Clean, fast, ultra-precise custom profiles

Every component is bar-coded for end-to-end traceability - from factory floor to 12 certified 4m × 2.2m lifting cages ready for site delivery.

Site-to-Shop Efficiency

Capture measurements instantly with the FabShop Mobile app (iOS & Android). Detail rectangular or round duct on-site and transmit directly to our CAD team - eliminating hand sketches and accelerating revisions.

Ductwork Solutions

Fully custom ductwork engineered to your exact specifications

Precision fabrication for total system compatibility

From high-rise commercial to critical healthcare environments, Cooke cuts projects down to size - faster, smarter, leak-free.

Documentation

Enquiry about Ductwork

Got any questions?