- Home >

- Products >

- Heating >

- Buffer Tanks

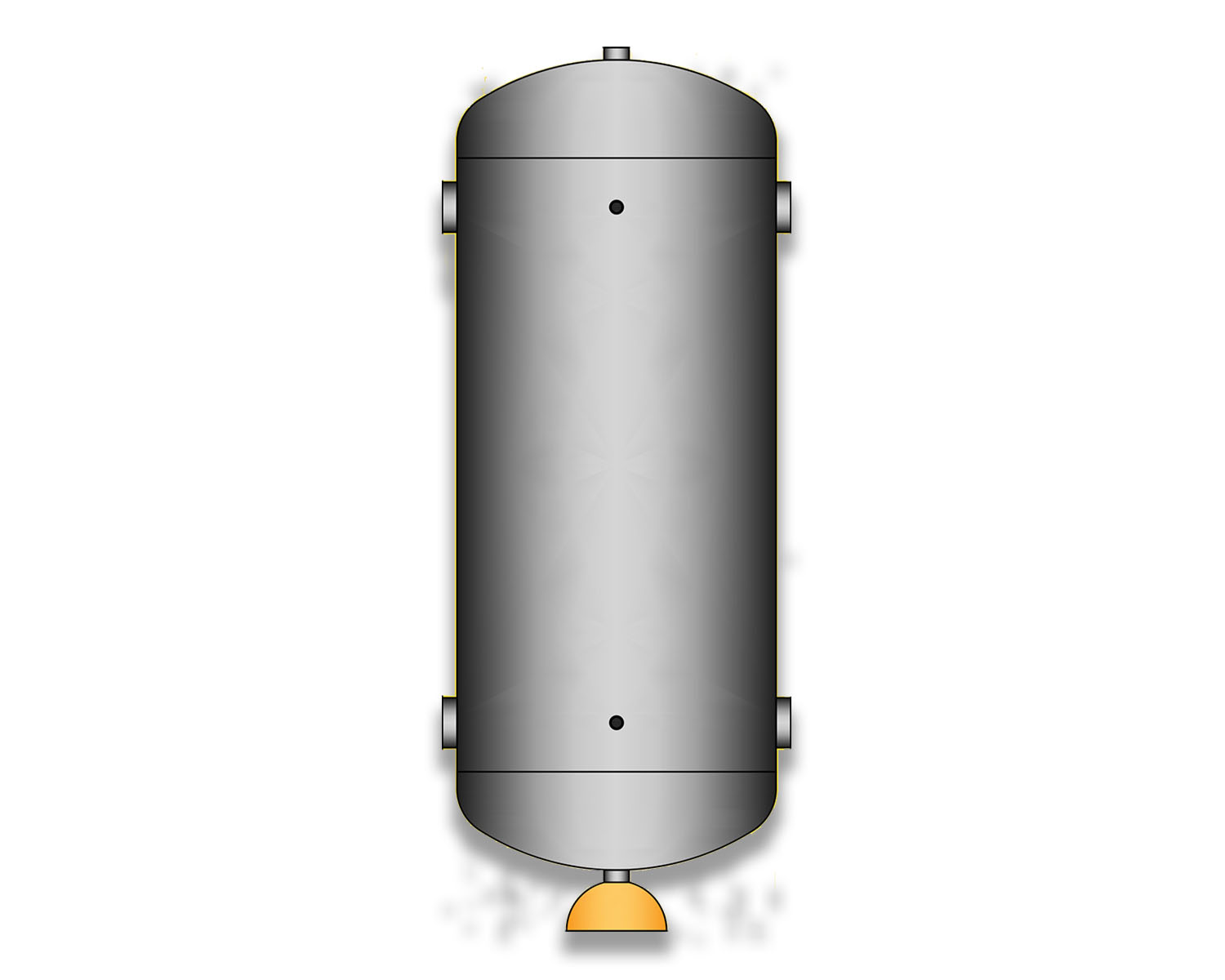

Bespoke Buffer Tanks

Based on the standard VT, TANKO, TANKO MIX, and TANKO HOT series, the TLR range of buffer tanks for cooling and heating water extends the possibility of customising the tanks to adapt them to a very wide range of needs, allowing both the thermal performance of the various components and their arrangement in the layout of the system to be optimised.

There are a large number of complete options to choose from:

Capacity: From 100L to 5000L

Version: They can be manufactured, in the larger sizes, with LOW and EXTRA-LOW heights to allow them to be installed in circumstances where the available height is not sufficient for the standard measurement;

Operating Pressure: From 6bar to 10bar;

Construction Material: Carbon steel externally painted (TLR-G), carbon steel fully hot dipped galvanised (TLR-Z), or AISI 316L stainless steel (TLR-X) pickled and passivated;

Insulation: Rigid foamed polyurethane in thickness 55mm & 70mm for cooling and heating circuits (TLR-C);

Insulation: Closed cell anti-condensation expanded elastomer in thickness 20mm, 40mm or 60mm for cooling circuits;

Insulation: Closed cell anti-condensation expanded elastomer in thickness 20mm coupled with 75mm thick PLFH (polyester fibre) thermal insulation, suitable for mixed hot/cold systems where it is necessary to guarantee perfect operation during both winter and summer modes;

Insulation: PLFH (polyester fibre) thermal insulation in thickness 100mm for tanks installed in heating systems;

External Cladding: Technical PVC fabric or embossed aluminium sheeting for external installation;

Type Of Connections: Threaded (GAS/M) or Flanged (PN16);

Internal Flow Disruptors: With micro-perforated plate or three offset flow dividers, for optimising the thermal distribution inside the tank.

The TLR, thanks to its modularity, can truly be adapted to all situations, either for technical reasons or for appearance, to achieve a buffer tank bespoke to the system and to obtain greater order and space inside the thermal system, with the advantage of reducing the production and maintenance costs of the various components present.

Documentation

Enquiry about Bespoke Buffer Tanks

Got any questions?